Kaliko Journal is a free newsletter about natural dyeing, textiles, art practice, and life by Ania Grzeszek. This publication is divided into two sections: ”Plant Dyeing” and “Studio Practice”. You can manage your subscription by clicking “Unsubscribe” at the bottom of the email and opting IN and OUT of the sections that interest you. This is also where you can pledge your financial support for this publication, which would help me continue to sustain it.

Feel free to share parts of this letter wherever and with whomever you’d like, remembering to tag me. If you want to support my work, subscribe to this publication and/or purchase my handmade products. Take care of yourself wherever you are.

Little did I know when I put these newly dyed sheets onto my duvet that I would spend the next few days under it, overcame by fever. Well, at least I am sick with style! And I am still sending out this tutorial, because I love sticking to the plan. I am starting to question my weekly publication schedule, though, so this is something I will have to think about going forward, especially that I might—or might not—be getting more on my plate in two weeks time. Hush hush for now!

This make turned out to be quite a challenge so if you’re a beginner, you might want to start with simpler/smaller projects. The process is not that difficult, but there are quite some ingredients you will need, as well as a large container, if you want to go as big as I did.

This recipe works for block printing, screen printing and painting. It can be used for making iron paste, as well as aluminium paste, that can be applied to the textile and dyed afterwards. Depending on the mordant (and the dye) you choose, the final outcome can also be multicoloured. But even a simple graphic and monochromatic pattern can make for a great project, as illustrated below. So have a look at the process and, hopefully, enjoy trying it out.

What you need

For mordant paste:

iron acetate: steel wool + white vinegar

OR iron sulfate + white vinegar + soda ash (sodium carbonate)

gum to thicken (guar gum / gum arabic)

water

For removing the gum and netralizing

wheat bran

chalk (calcium carbonate)

For dyeing

tannin-rich dye

…and of course, as always in natural dyeing, scoured textiles made with natural fibres, and utensils you don’t use for cooking food.

Making the printing paste

For this project I made a paste with iron, though you could swap the iron for aluminium, or mix both for an in-between final color. The paste can be applied to the (dry!) textile either using blocks, or brushes or printed with a silk screen.

To make iron acetate, you can either refer to my recipe from last week, or go as follows:

dissolve ca. 5g of iron sulfate in very small amount of warm water

add ca. 100ml of white vinegar solution (5%) OR 20ml of white vinegar essence (25%) mixed with 80ml water

combine with ca. 2,5g of soda ash

At this point the solution will produce big amounts of froth, so make sure your container is big enough.

Now you can add gum to thicken the paste. Most recipes I found refer to guar gum, which is quite strong and rather slick. I worked with gum arabic instead, because that’s what I could find locally. It is more sticky than slick and considerably less strong. I start with quite a runny paste and adjust it as I go. For guar gum, that would be ca. 1g. For gum arabic, ca. 20 times that, so 20g. Both gums are water soluble and need ca. 30 minutes to thicken in the solution. If you have access to guar gum, that would be my first choice.

Applying the paste

That’s the fun part! Sky is the limit, and, as said, you can use whatever you want to make a pattern. The paste should be thick enough not to run. I worked with a squeegee that I used as a block for printing lines. You can work with wooden blocks, rubber stamps, silk screens or brushes. The fabric should be completely dry. Because the bedding was so big, I wish I chose an easier pattern, but well, I started so I had to finish. It took around 8 hours over 2 days to print all the lines! I applied the paste to my squeegee with a brush and stamped onto the fabric. The color at this point is rusty-beige and only slightly visible. Iron binds with the fibres only where it was applied to and this is where the final image will appear.

After printing one side, I let the sheets dry for a day or two, making sure that I don’t smudge the pattern. Because the paste soaks through both layers, I then stuck the sheets to the window, and made identical marks on the other side. I let them dry again and then I could proceed to the next step.

Removing the gum and neutralizing iron

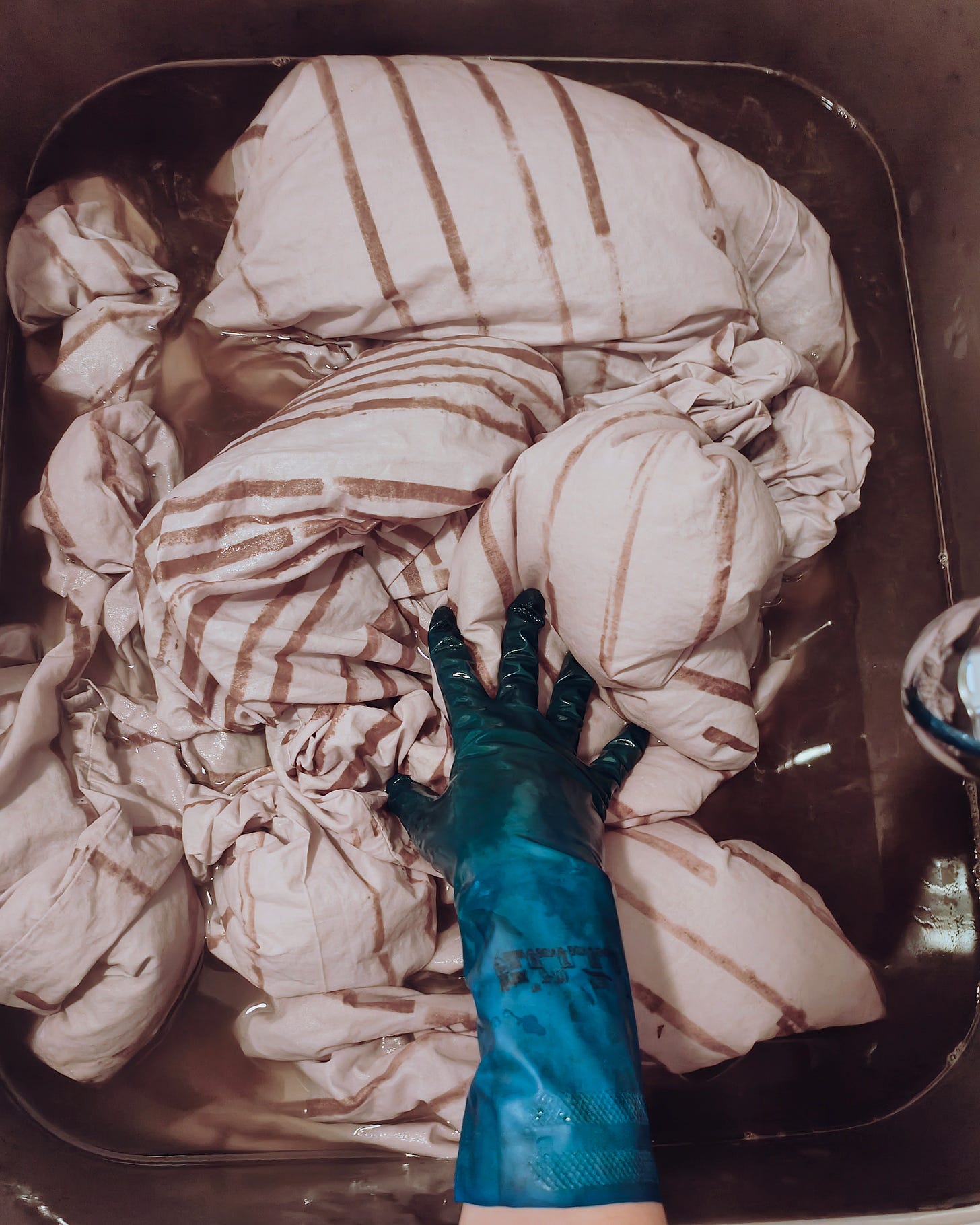

I am lucky to have a studio with a big 100L sink that I got for my dyeing projects, so I could rinse and neutralize all sheets in one go. You could use your bathtub to do the same, or simply start with a smaller project. First, rinse your fabric thoroughly. Some gum will dissolve already at this point (remember it’s water soluble?), and loose iron particles will be removed, too.

After that, you need to neutralize the acetic paste, by soaking it in chalk solution. You might also want to add some wheat bran, which has enzymes that help to remove all residue gum from the fabric. All that should be left after this step is iron bound with fibres, without any additional substances that might stop the dye from binding with the mordants. For the chalk and wheat bran solution, you should add ca. 10g of chalk for 1L of water. I certainly used less, as 1kg chalk sounded quite excessive to me, and it still worked well. I also added one cup of wheat bran, that I tied inside a muslin cloth and let soak in the solution for a few minutes.

Place your printed fabric in the solution and work it for a few minutes to fix the iron acetate and to remove the gum. The solution might get slightly muddy brown. After it’s done, rinse it one last time in clear water to remove chalk.

Dyeing the fabric

You can proceed directly to dyeing now. I used my big sink again that I filled with hot water and added a few liters of a very concentrated dye. I chose tara powder as a dye. It’s almost transparent in color, so it wouldn't show on the un-mordanted background, but it turns very dark when combined with iron. It is perfect for contrasting prints. You can use other tannin-rich dyes instead, like oak galls, sumac, tannic acid, black tea, cutch, etc. I simmered ca. 100g of tara powder in a few litres of water for an hour. After the dye was extracted, I sieved the liquid through a muslin cloth to catch the powder and poured it to my sink dyebath. I placed the sheets in the dye and the pattern immediately started turning dark. I moved the sheets regularly and let them dye for an hour.

When dyeing was done, I rinsed the sheets a few times. It’s best to use your washing machine for that purpose, but I don’t have one in my studio. It took quite some time to get to the point where the color didn't bleed anymore. I added some white vinegar (ca. 100ml) to the final rinse, to make the now-alkaline (because of chalk!) pattern more grey and that was, finally, the end of my biggest project to date.

So now, writing it from under my new sheets, I am wondering if it was worth it. It certainly took longer than anticipated, because of the sheer size of the fabric and because the pattern turned out surprisingly intricate. But, in my experience, the bigger the project, the more challenges it poses, and the more I can learn, which was certainly the point. New ideas that this exercise sparked: screen printing with mordants, for sure! How about you? Any new projects in mind?

In case you missed it

Here’s, as always, a video of the entire process

I am running in-person workshops again! Starting with Bundle Dyeing on February 18th, I then scheduled an Intro to Plant Dyeing class on March 4th and a Natural Tie-Dye workshop on March 18th. I am also available for private classes (1-5 people in my studio), where you can choose the curriculum and the date, as well as team events at your location.

In the recent Chat we showed the projects we worked on the previous week. If you’d like to join and show us what you make, you can post your make via the Substack App. I shared my newest painting which I was chuffed to finish last week.